Description

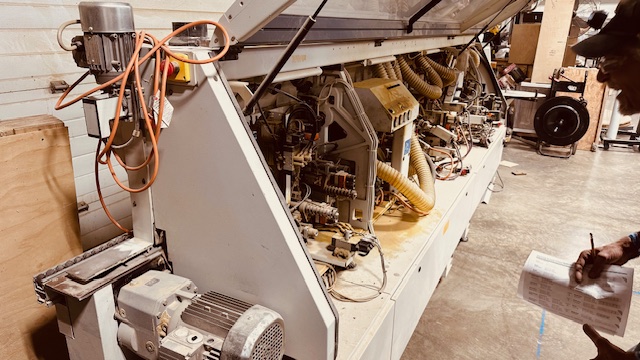

Used 2011 Biesse Akron 440 Edgebander

Click the link below to see a short video of the machine

https://popvideo.io/v/2143190301/Used-2011-Biesse-Akron-440

Automatic single sided edgebanding machine for the application and processing of flat edge-banding material in coils

(melamine, PVC, ABS, veneer) and in strips (solid wood, HPL, prepared veneers etc.)

- Premilling

- Anti Adhesive

- Glue unit

- End trim

- Tilting top and bottom trimming ‘

- 2 motor corner rounding with computer controlled radious change

- Profile scrapper

- Flat scrapper

- Buffing

- Hot air blower

TECHNICAL CHARACTERISTICS AKRON 400

- Panel height: from 10 to 60 mm

- Panel height with corner rounding unit: from 10 to 35/60 mm (depending on profiles)

- Height of edge-banding material: from 14 to 64 mm

- Thickness of edge-banding material in rolls: from 0.4 to 3 mm

- Thickness of edge-banding in strips (*): from 0.4 to 10 (12) mm

- Min panel length: 140 mm

- Min panel width (with length 140 mm): 85 mm

- Min panel width (with length 250 mm): 50 mm

- Track feed speed: 12 & 18 m/min

- Glue pot capacity: 2 Kg (approx)

- Glue pot heating time at ½ load: 10 minutes (approx.)

Pre-milling unit FI-502 axis driven by brushless motor

- Gluing unit VC-511 axis driven by brushless motor

- End trimming unit IN-801

- Tilting trimming unit RI-501 axes driven by brushless motor

- 2 motors corner rounding unit CR-200V with FAST 4 positions

- Edge scraper RBK with Dust extraction

- Glue scraper RCC-701 with Dust extraction

- Brushing unit SP-501

- Hot air blower PH-501

Numeric Control switch board

Numeric Control Color TS10 with 10”

The Numeric Control TS10 allows to manage the machine and its functions.

Technical characteristics:

- Graphic 10” LCD display TOUCH SCREEN, 640×480 pixel.

- Operating system WINDOWS CE.

- USB port.

Some of the included functions:

- Automatic start-up of the motors as wriiten in the program.

- Direct button for the choice of the second passage.

- Managing of 8 numerical axis.

- Lists of programs with manual and/or automatic start.

- Error diagnostic with codes and comments.

- Production statistic data.

- The touch screen is mounted on an adjustable control arm

- TS06

- Machine programming softwareSINTRA

- Total installed power13 KW

Documents